In the rapidly evolving world of railway infrastructure management, precise measurement and detailed environmental data are crucial for safety, maintenance, and planning. Among the various technologies available, LiDAR (Light Detection and Ranging) has emerged as the best suited measurement technology for railway environment scanning. Here are the 7 reasons why: LiDAR technology is revolutionizing the … Continued

What is it, how can you achieve it?

Track geometry is particularly important in the design, construction and maintenance of rail networks. It is the three-dimensional geometry of track layouts. Track geometry also takes into account a variety of measurements and standards, such as speed limits and other regulations in the areas of track gauge, alignment, elevation, curvature and track surface. Building, maintaining and optimising rail networks to achieve perfect track geometry ensures the safety of passengers and timely delivery of rail freight.

Entering the digital era of track measurement

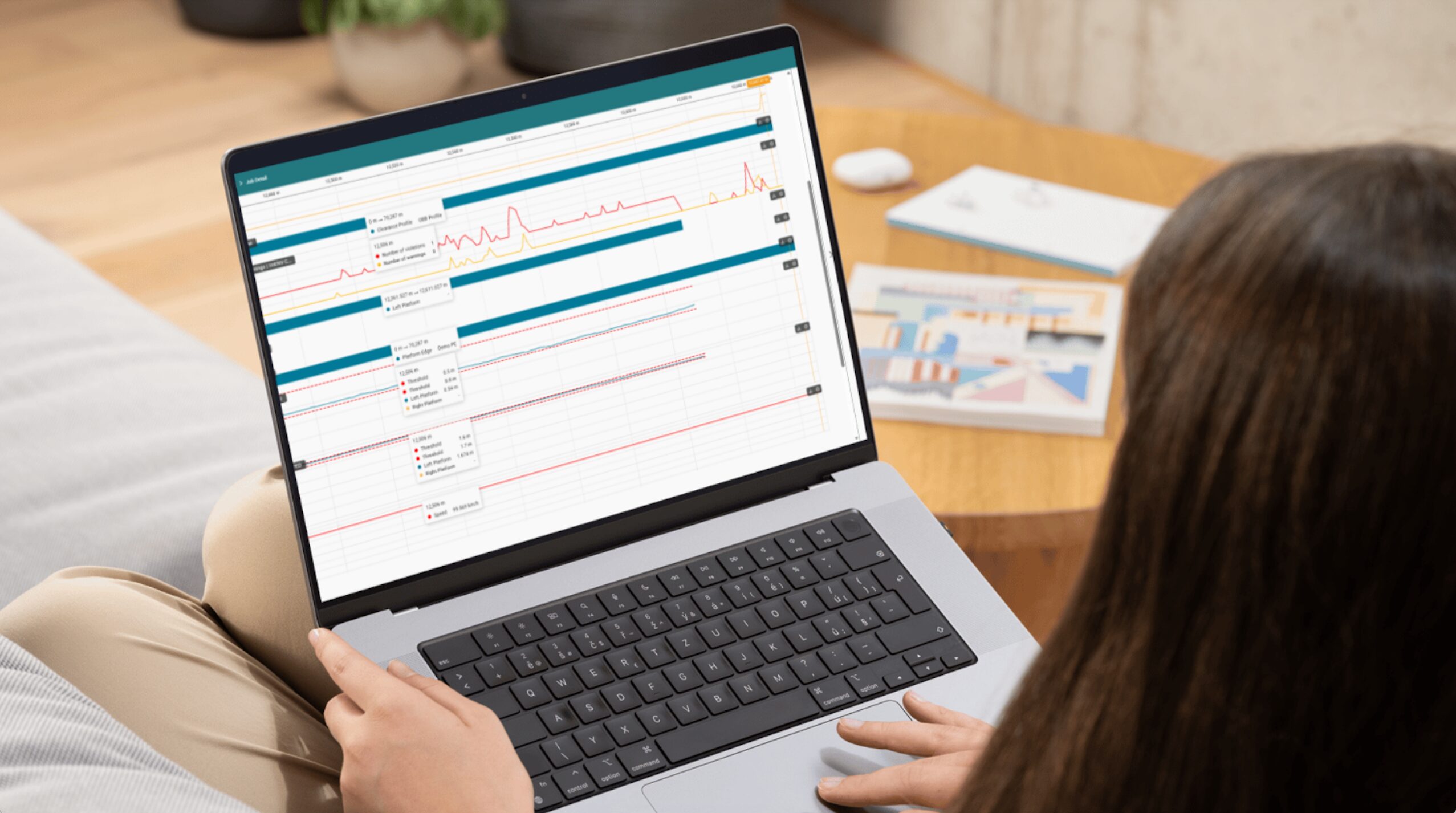

With the combination of innovative software, high-tech cameras and light tmc has developed a measuring system that can see spatially, like us humans. With this solution, you can identify markers, that are mounted next to the railway tracks to precisely calculate the horizontal and vertical distance of the railway track position – with an unmatched speed of up to 80 km/h. This solution is tmRTG, it is available together with the markers and a detailed deployment guide: read more about tmRTG or contact us for a detailed presentation.

Why digital track geometry measurement pays-off

Traditionally, track measurements are carried out by closing a track section and having professionals measure the tracks with a tacheometer. By switching to tmRTG, your benefits are:

- Fastest, safest type of track measurement

- Highly precise

- No track closures

- Resource efficiency – less time and cost

- Parameters required for track maintenance are directly transferred to the infrastructure manager

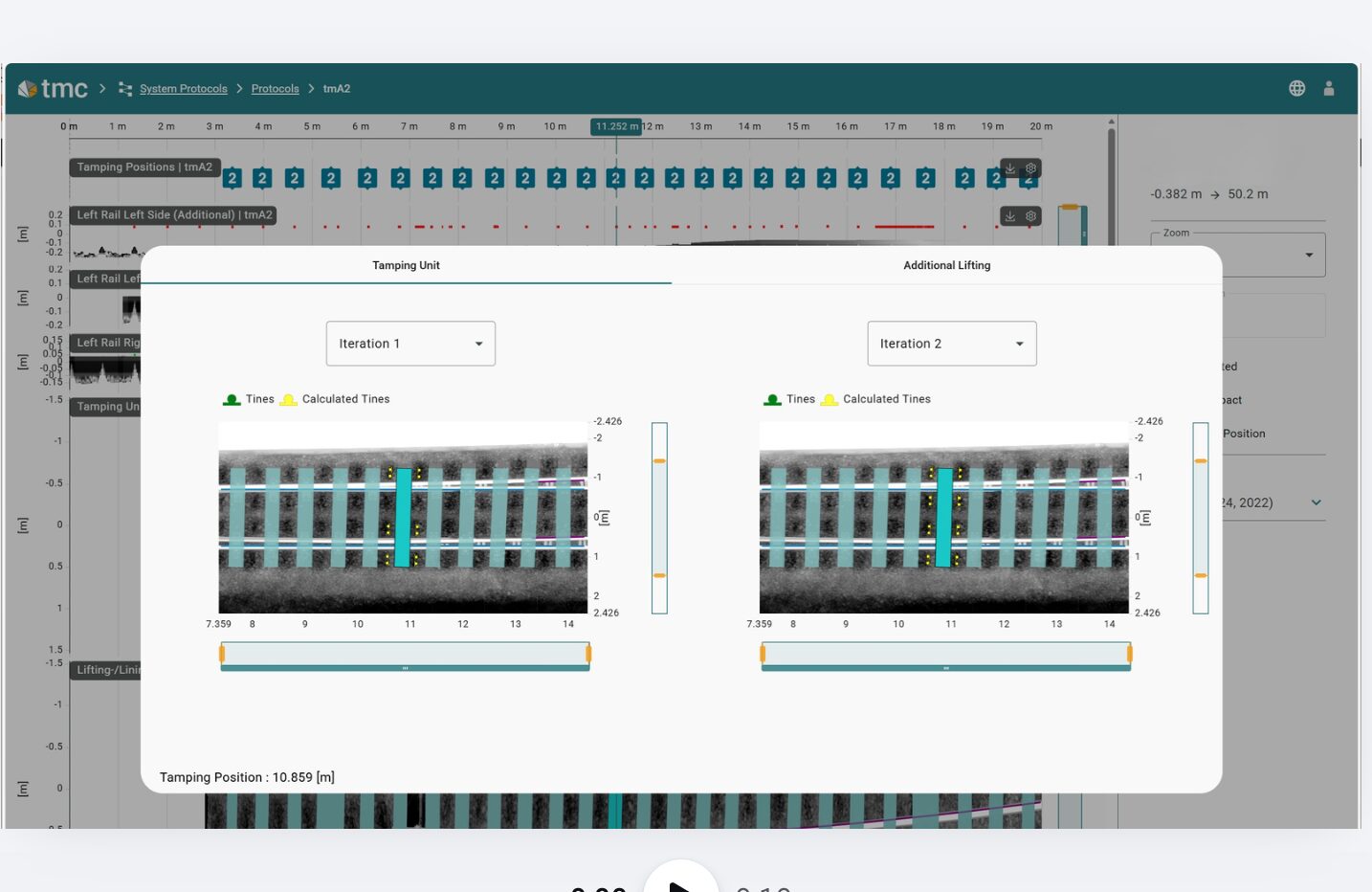

How does digital referenced track geometry work?

Referenced track geometry measures the track position relative to fixed points. Fixed points can be markers that are specifically designed for this purpose and have to be mounted once on masts. tmc’s tmRTG solution consists of innovative software and high-tech cameras that measure the horizontal and vertical distance to the markers. During post-processing the measured track position is compared to the nominal track position – onboard a track machine or measuring vehicle and in the backoffice. From this comparison, the correction values can be exactly derived and directly imported to better guide and support tamping machine and maintenance staff. Additionally, the Absolute Track Geometry can be calculated to provide the track position in absolute coordinates.