In its latest update, tmMCO introduces several new features aimed at enhancing user experience and operational efficiency. These features encompass user position, geofencing capabilities, and a comprehensive machine maintenance module (tmM3), providing users with greater control and insight into their machinery management.

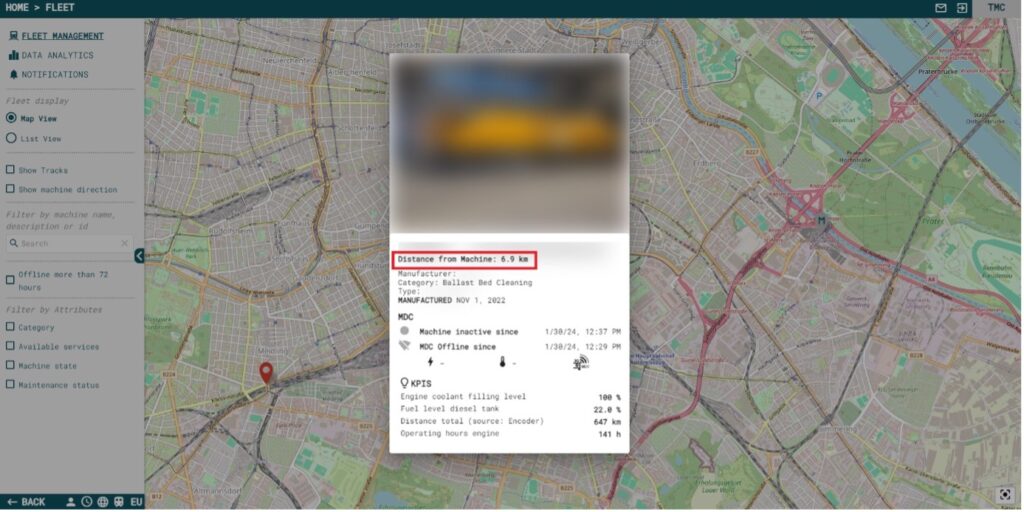

User Position

One notable addition to tmMCO is the integration of Browser Geolocation. Users can now enable their position on the map and list view within tmMCO. This functionality enables real-time calculation and display of the distance between the user and each of the machines, facilitating quicker responses to emergencies or necessary tasks such as tamping. By instantly pinpointing the nearest available machines, this feature streamlines shift planning and improves overall operational efficiency.

This feature operates similarly to popular location-sharing services like Google Maps, Apple Find My, WhatsApp, or Uber, tailored specifically for track machines.

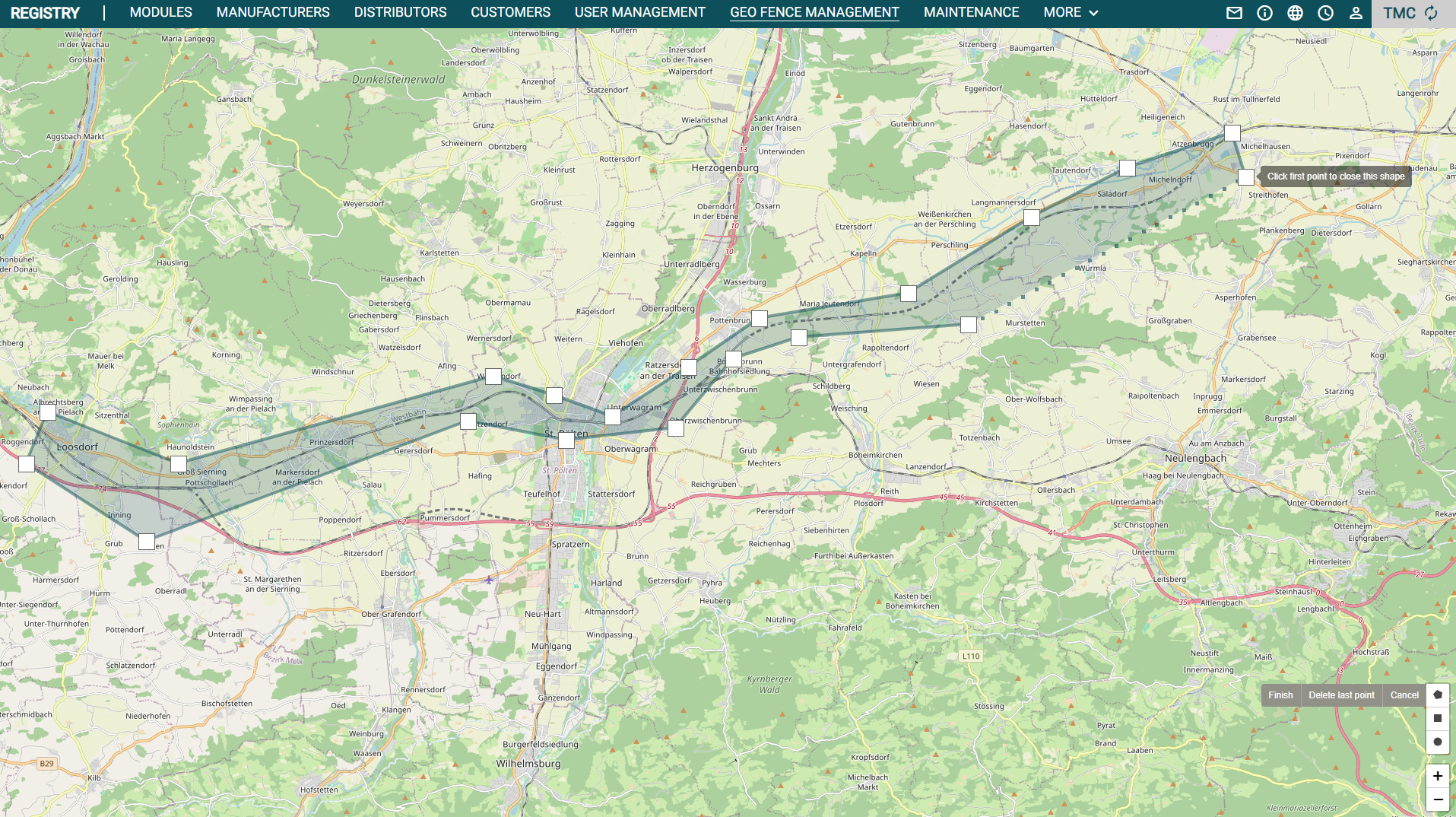

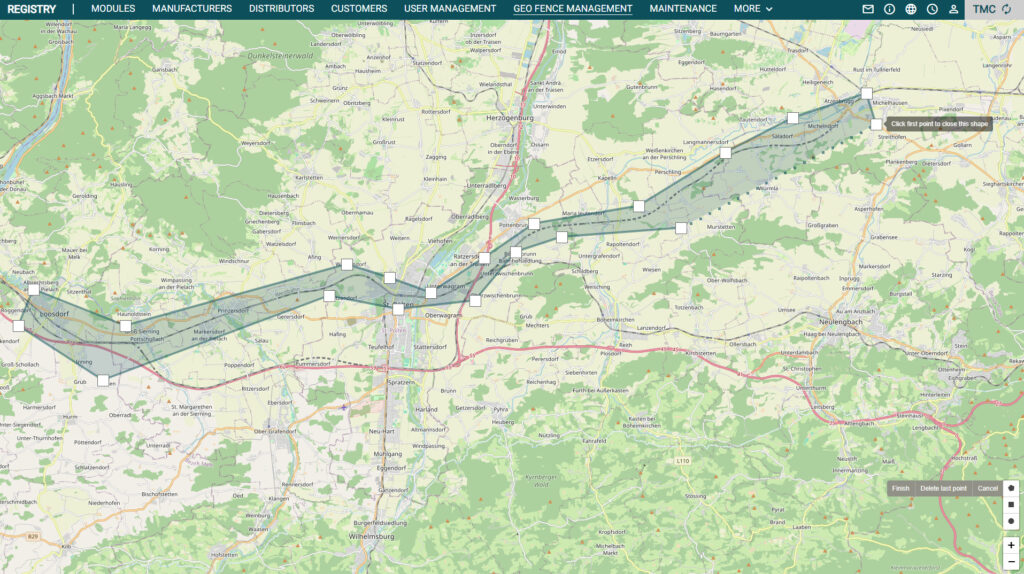

Geofencing

Another sought-after enhancement is the introduction of geofencing capabilities. Users can now define geofences for their machines, receiving email alerts whenever a machine enters or exits a designated area. This feature proves invaluable for tracking machine movements, providing notifications for arrivals at workshops, depots, or specific worksites. With the flexibility to set multiple geofences, users gain enhanced control over machine monitoring and management. This is not a mandatory feature and can also be disabled.

Machine Maintenance Modul (tmM3)

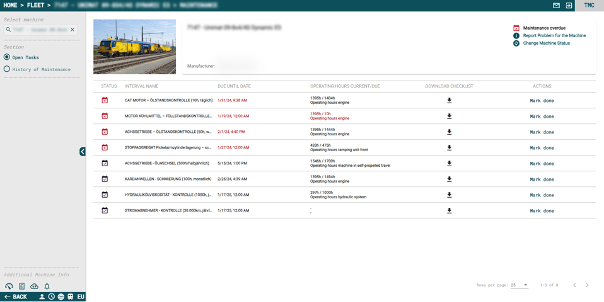

The new Machine Maintenance Module (tmM3) offers comprehensive tools for managing machine maintenance schedules and tasks. Users can establish maintenance schedules based on either cyclical intervals or time-based criteria, such as after a certain number of operating hours. Additionally, tmM3 allows users to upload checklists, utilize vendor-provided maintenance guidelines, or manually input maintenance parameters.

The maintenance status for each machine with activated tmM3 is prominently displayed, enabling users to track ongoing maintenance activities. This provides users with an easy to access overview to ensure compliance with maintenance schedules. Upon completion of maintenance tasks, users can easily update the machine’s status within tmM3. Furthermore, should users encounter machine issues outside of scheduled maintenance, they can promptly register these problems within tmM3, facilitating swift resolution.

A comprehensive maintenance work log is accessible for each machine, providing users with a detailed history of maintenance activities and ensuring optimal machine performance.

With these latest features, tmMCO continues to evolve as a versatile and indispensable tool for machine management. From enhanced user positioning to geofencing capabilities and a robust maintenance module, tmMCO empowers users with greater control, efficiency, and insight into their machinery operations.