tmc’s Machine Data Connector now enhances Robel Rail Automation’s innovative ROBOT. The ROBOT from Robel Rail Automation is a cutting-edge solution designed for railway maintenance. Mounted on a flat wagon, it deploys a robotic frame equipped with a welding robot and a tool robot, which perform essential 3D vision computer-assisted maintenance tasks directly on the tracks, such as: scanning, measuring, milling, pre-heating, welding, ground connection, and grinding of switches and tracks.

tmMDC: Bringing Smarter Control and Transparency

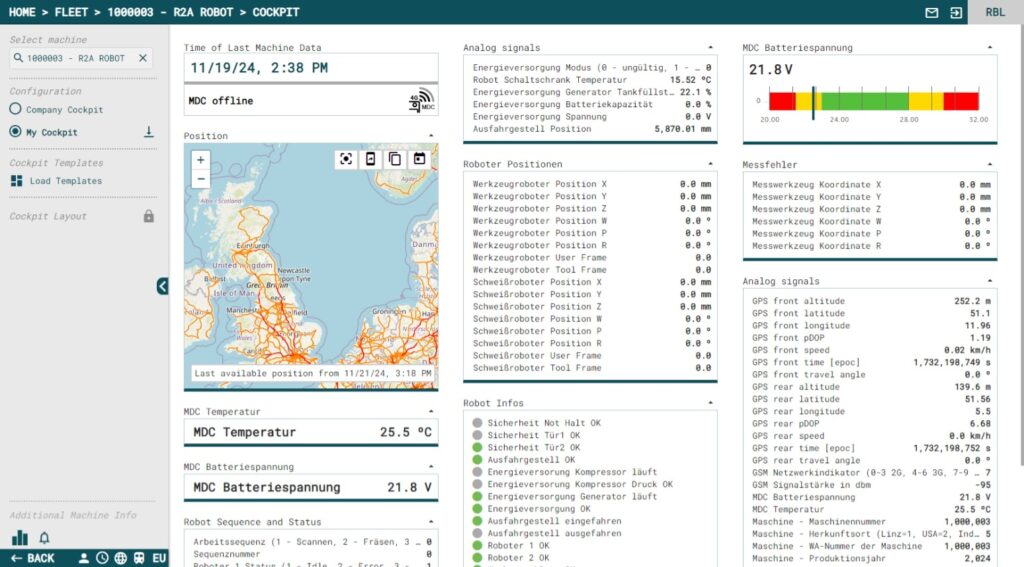

The integration of tmMDC into the ROBOT brings new levels of operational efficiency and transparency to the ROBOT’s maintenance work. With tmMDC, every critical data point – from GPS coordinates to machine temperatures, battery status, and tool positions – is meticulously recorded. This means operators and engineers can track exactly what the machine is doing, when it’s doing it, and how it’s performing.

Key features include:

- Real-time tracking: Know exactly where the machine is and what it’s doing at any given moment.

- Comprehensive data recording: Record parameters like machine state, work steps, and energy usage, and use this data for continuous improvement.

- Seamless communication: Using TRDP (Train Real-Time Data Protocol), tmMDC ensures smooth, reliable communication for mission-critical operations in railway construction and maintenance.

This continuous data flow is not just about monitoring the ROBOT—it’s about using that data to optimize performance and drive future improvements in vehicle and machine design.

Figure 1: Screenshot of tmMDC onboard of the ROBOT

Collaborative Innovation between Robel Rail Automation and tmc

For Jochen Nowotny, CEO of tmc, the collaboration with Robel Rail Automation has been a highlight of this year. “Integrating tmMDC with the ROBOT is a perfect example of how data can transform maintenance processes. We are excited to be part of this innovative step forward with our innovative partners at Robel Rail Automation. Together, we enjoy pushing the boundaries of digitalization and automation in the railway industry”

And for Robel Automation, the partnership has proven invaluable in ensuring both operational transparency and efficiency. Gregor Gruber at Robel Rail Automation says ” The integration of tmMDC with our systems, supported by Fabian Wimberger, has been outstanding. The collaboration with tmc is incredibly hands-on and we look forward to using the data collected from the tmMDC.”

A Vision for the Future

The ROBOT is the second machine of Robel Rail Automations fleet to be equipped with tmMDC, alongside with the highly sought after inspection vehicle ROSPECT. The machines with tmc’s tmMDC are performing well in ongoing tests and applications like those with ProRail, VolkerRail, and Structon. The ability to collect and analyze operational data in real time means engineers can identify areas for improvement, optimize machine settings, and even foresee maintenance needs before they arise.

By enhancing both the efficiency and transparency of the ROBOT, tmMDC is supporting Robel RailAutomation and, as one of our bestsellers, it’s shaping the future of railway infrastructure maintenance vehicles – making them smarter, efficient and more transparent – one track machine at a time.

Are you looking to retrofit your track machines with tmMDC or ready to purchase a new machine with tmMDC? Contact us, we are ready to support you on this journey.